|

Item |

|

Unit |

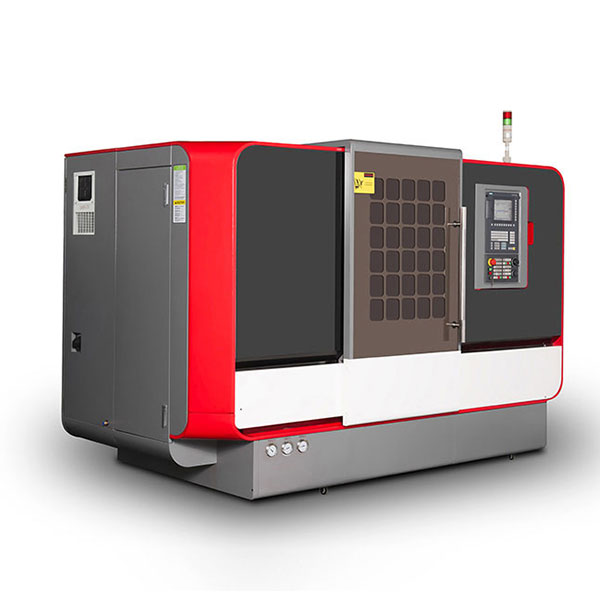

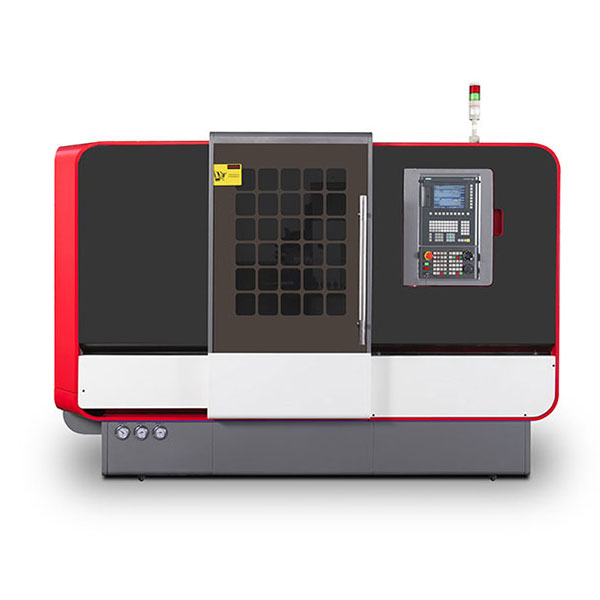

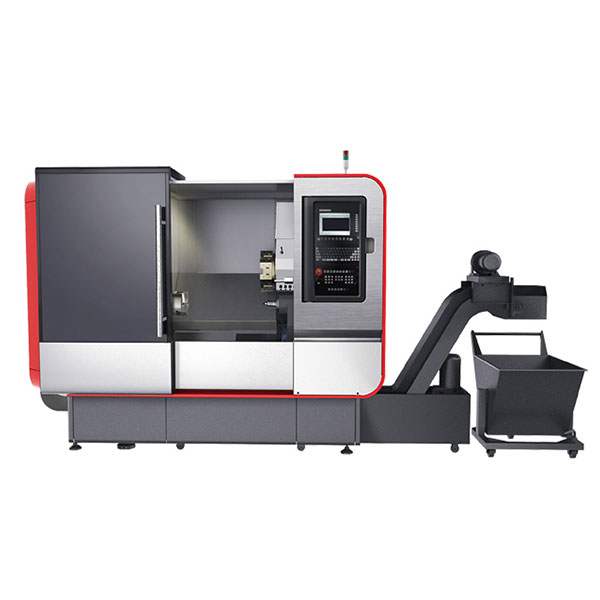

AE45Y |

AE55Y |

|

Capacity |

Bed slant angle |

° |

45 |

45 |

|

Swing over bed |

mm |

Φ510 |

Φ520 |

|

Max. turning diameter (shaft/disc workpiece) |

mm |

Φ230/Φ420 |

Φ280/Φ500 |

|

Max. length of workpiece |

mm |

720 |

720 |

|

Max. turning length |

mm |

500 |

500 |

|

Spindle |

Spindle nose type |

- |

A2-6 |

A2-6 |

|

Spindle bore |

mm |

Φ62 |

Φ62 |

|

Allowable bar diameter through spindle bore |

mm |

Φ55 |

Φ55 |

|

Max. spindle speed |

r/min |

4000 |

4000 |

|

Chuck |

inch |

8 |

10 |

|

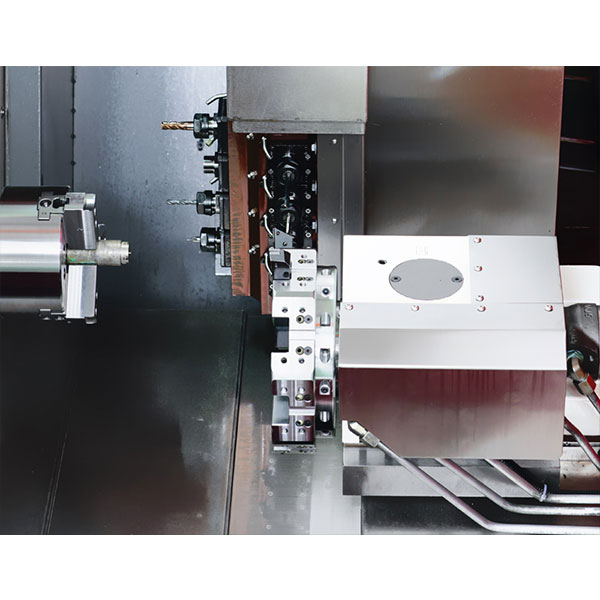

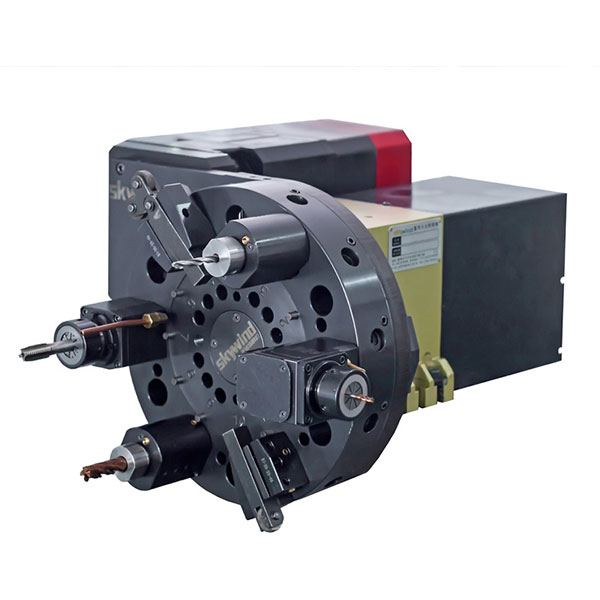

Turret |

Cross section of tool shank |

mm |

20×20 |

25×25 |

|

Turret type |

- |

Power tooling turret |

Power tooling turret |

|

No. of switching positions |

- |

12 |

12 |

|

Boring bar diameter |

mm |

Φ25 |

Φ32 |

|

Turret motor power |

kW |

2.7 |

2.7 |

|

Max. speed of turret motor |

r/min |

3000 |

3000 |

|

Live tool holder |

- |

BMT45 ER25 |

BMT55 ER32 |

|

Stroke & Feed |

X-axis effective stroke |

mm |

215 |

255 |

|

Y-axis effective stroke |

mm |

±50 |

±50 |

|

Z-axis effective stroke |

mm |

500 |

500 |

|

Rapid traverse speed of X-axis/Z-axis |

m/min |

X:30/Z:30 |

X:30/Z:30 |

|

Rapid traverse speed of Y-axis |

m/min |

15 |

30 |

|

Max. feeding speed of X-axis/Z-axis |

m/min |

5 |

5 |

|

Tailstock |

Tailstock quill diameter |

mm |

Φ80 |

Φ80 |

|

Tailstock quill taper |

- |

MT5 |

MT5 |

|

Tailstock quill max. stroke |

mm |

100 |

100 |

|

Accuracy |

Repeat positioning accuracy of X-axis/Z-axis |

mm |

0.003 |

0.003 |

|

Positioning accuracy of X-axis/Z-axis |

mm |

0.005 |

0.005 |

|

Positioning accuracy of C-axis |

° |

0,001 |

0,001 |

|

Others |

Spindle motor power |

kW |

11 |

11 |

|

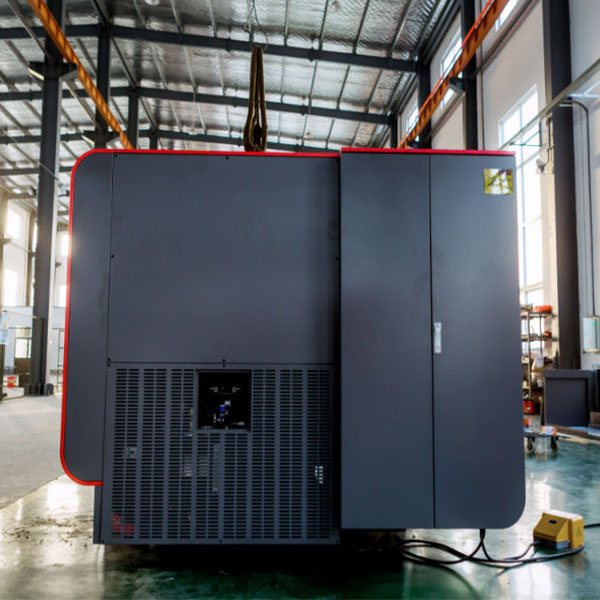

Electricity capacity |

KVA |

30 |

30 |

|

CNC system |

- |

Fanuc 0i-TF (5) |

Fanuc 0i-TF (5) |

|

Length×Width×Height |

mm |

2600×1700×1960 |

2650×1850×1850 |

|

Net weight |

kg |

3800 |

4500 |